Shrink tunnel

Shrink tunnels are advanced thermal systems designed to apply controlled heat to shrink film, creating a secure, tamper-evident seal around products. Ideal for industries requiring high-speed, precision packaging (e.g., food, pharma, cosmetics), these systems ensure product integrity and brand appeal.

Multi-Zone Precision Heating: ±1.5°C uniformity across 3–12 zones (PID-controlled).

Advanced Thermal Recovery: ≤3-second heat recovery after film loading. Zero cold zones ensure uniform shrinkage across irregular shapes.

Dynamic Conveyor Adjustments: 0–15 m/min speed with ±0.2% accuracy. Anti-static belts reduce film misalignment (tested at RH <30%).

Ultra-Low Noise Operation: ≤65 dB(A) at full load. Vibration damping: <2µm/s²

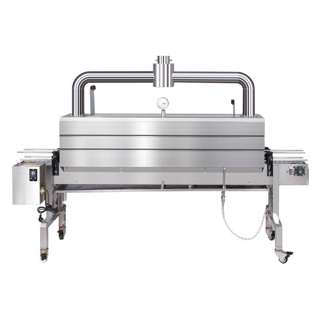

BS Series

BSX Series

BSZ Series

Technical specification

| Model | Shrink Type | Voltage | Power | Rate(m/min) | Shrinking Oven(LxWxH) | Weight | Dimension(mm) |

|---|---|---|---|---|---|---|---|

| BS-4020 | Heat-PVC/POF | 220V/380V | 6.8kW | 0-10 | 800x400x200mm | 200kg | 1600x600x1250 |

| BS-4522 | Heat-PVC/POF | 220V/380V | 7kW | 0-10 | 1500x450x220mm | 210kg | 1600x750x1350 |

| BS-4525 | Heat-PVC/POF | 220V/380V | 8kW | 0-10 | 1500/1800x450x250mm | 220kg | 1600x750x1350 |

| BS-5530 | Heat-PVC/POF | 220V/380V | 15kW | 0-10 | 1500/1800x550x300mm | 230kg | 1900x800x1400 |

| BS-6530 | Heat-PVC/POF | 380V | 18kW | 0-10 | 1500/1800x650x300mm | 250kg | 1900x1000x1400 |

| BS-7530 | Heat-PVC/POF | 380V | 18kW | 0-10 | 1800x750x300mm | 280kg | 2200x1050x1400 |

| BS-8530 | Heat-PVC/POF | 380V | 20kW | 0-10 | 1800x850x300mm | 300kg | 2300x1100x1400 |

| BSX-4535 | Heat-PVC/POF/PE | 380V | 16kW | 0-15 | 1200x450x350mm | 150kg | 2200x700x1140 |

| BSX-5040 | Heat-PVC/POF/PE | 380V | 19kW | 0-15 | 1500x500x400mm | 290kg | 2500x750x1140 |

| BSX-6040 | Heat-PVC/POF/PE | 380V | 20kW | 0-15 | 1800x600x400mm | 210kg | 2800x850x1140 |

| BSX-7050 | Heat-PVC/POF/PE | 380V | 25kW | 0-15 | 1800x700x500mm | 450kg | 2800x930x1600 |

| BSX-8050 | Heat-PVC/POF/PE | 380V | 28kW | 0-15 | 1800x800x500mm | 500kg | 2800x1030x1640 |

| BSX-9050 | Heat-PVC/POF/PE | 380V | 32kW | 0-15 | 2000x900x500mm | 550kg | 3500x1130x1680 |

| BSZ-1600 | Steam | 220V | 9kW | 50-170 | 1000x95x275mm | 130kg | 1600x600x1200 |

| BSZ-2450 | Steam | 220V | 9kW | 50-170 | 1700x120x310mm | 150kg | 2450x500x1600 |

Semi-auto Sealer and Heating tunnel

The ultimate packaging powerhouse: our semi-auto sealer with heating tunnel. This ingenious machine seamlessly combines sealing and heating technologies, revolutionizing your packaging process and delivering flawless results.

Precision Control: Digital PID temperature controller ensures ±2°C accuracy.

Uniform Heat Distribution: Forced hot air circulation system ensures ±3°C uniformity across the tunnel.

Industrial Durability: Reinforced steel frame with powder-coated finish resists corrosion and mechanical stress.

| Model | BS-4020S(Heating Tunnel) | FQL-450S(Semi-Auto Sealer) |

|---|---|---|

| Tunnel size (LxWxH) | 800*400*200mm | N.A. |

| Wrapping size (LxWxH) | N.A. | 500*300*125mm |

| Speed | 0-15 m/min | 0-18 bag/min |

| Film | POF/PVC | POF/PVC |

| Temperature | 0-300 degree | 0-300 degree |

| Voltage | 220V/380V | 220V |

| Power | 7.5KW | 4.5KW |

| Footprint | 1150*750*1050mm | 1060*720*1240mm |

| Weight | 80kg | 80kg |

Heating tunnel vIDEO

Maintenance guide

Daily

Inspect conveyor belt alignment (max. ±1.5 mm deviation).

Clean infrared (IR) heating elements with anhydrous ethanol to remove residue.

Log temperature uniformity (±2°C tolerance across zones).

Monthly

Lubricate chain drives and bearings using Molykote PG-65 high-temperature grease.

Calibrate PID controllers with a traceable thermocouple (accuracy: ±0.5°C).

Annually

Replace heating panels (service life: 8,000–10,000 hrs).

Conduct full-system safety audit per IEC 60204-1:2016.

Safety & Compliance

Lockout/Tagout (LOTO): Mandatory during maintenance (OSHA 29 CFR 1910.147).

Thermal Guards: Ensure radiant heat shielding is intact (surface temp ≤45°C per ISO 13732).

Emergency Stop: Test response time (<0.5 sec) monthly.

Common Operational Faults & Solutions

| Symptom | Possible Cause | Immediate Action | Tools Required |

|---|---|---|---|

| Uneven Heating | – Faulty IR heating element – Misaligned reflectors – Sensor calibration drift | 1. Check element resistance (target: 20–25Ω) 2. Realign reflectors to ±2° angle 3. Recalibrate Type K thermocouples | Multimeter, Infrared thermometer |

| Belt Slippage/Misalignment | – Worn drive chain – Loose tensioner – Debris on rollers | 1. Adjust belt tension (per torque specs) 2. Clean rollers with non-abrasive solvent 3. Replace chain if elongation >3% | Torque wrench, Caliper |

| Overheating Alarm | – Clogged HEPA filters – Failed cooling fan – PID controller error | 1. Replace filters (ΔP >50 Pa) 2. Test fan voltage (24V DC ±5%) 3. Reset PID parameters | Manometer, Oscilloscope |

| Intermittent Power Loss | – Loose terminal connections – Insulation breakdown (R <100 MΩ) – Phase imbalance | 1. Tighten terminals (10–12 Nm torque) 2. Perform Megger test at 500V DC 3. Balance phases (<5% variance) | Megohmmeter, Clamp meter |

| Excessive Vibration | – Unbalanced motor – Damaged bearings – Misaligned pulleys | 1. Balance motor using ISO 1940 G6.3 standard 2. Replace bearings (vibration >4.5 mm/s RMS) 3. Align pulleys (laser alignment tool) | Vibration analyzer, Laser aligner |

Notes: For persistent faults, consult the factory-certified service manual.