Tired of manually filling containers one by one?

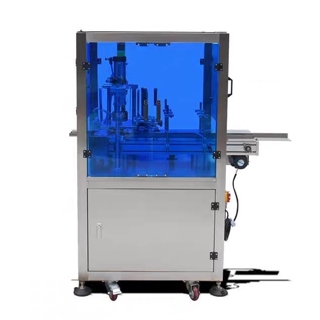

Our automatic filling machine does just that and more!

If you’re seeking a top of the line ‘filling machine’ that can effortlessly and expeditiously meet your container filling requirements, look no further than our automatic filling machine. It’s the ultimate resolution to your search.

Revamp Your Manufacturing Efficiency with Our Container Filling System.

The benefit of using a auto filling machine

The perfect solution for streamlining your production process and boosting your output.

Flexibility: Our filling machine is versatile and can handle various container types and product consistencies, from liquids to pastes to gels. You can adjust the filling capacity and rate to perfectly match your manufacturing needs.

Craftsmanship: Craftsmanship is essential to maintain the quality of your products and reduce waste. Our automated filling machine uses advanced sensors and controls to ensure precise filling measures with minimal variance.

Innovative language to describe efficiency: Our filling machine maximizes production output and minimizes labor costs with lightning-fast filling capabilities and automatic bottle positioning. Its easy-to-clean design saves valuable time for your team to focus on other important tasks.

line Filler

Liquid Filling Machine

Powder Filling Machine

Grain Filling Machine

Rotary Filler

rotary Filling Machine

line Filling Machine VS. Rotary Filling Machine

When it comes to selecting the perfect filling machine for your bottle, can, or jar filling needs, understanding the differences between a Line Filling Machine and a Rotary Filling Machine is crucial. While the Line Filling Machine prioritizes speed and integration into automated production lines, the Rotary Filling Machine offers exceptional versatility, precision, and adaptability to various container types. Explore the key distinctions to make an informed decision and optimize your filling operations for maximum efficiency and productivity.

Speed vs. Versatility

The Line Filling Machine boasts impressive speed capabilities, making it ideal for high-volume production lines that require rapid filling. On the other hand, the Rotary Filling Machine offers exceptional versatility, allowing you to fill various container types and sizes with precision and ease.

Production Line Integration

The Line Filling Machine is designed for seamless integration into automated production lines, optimizing efficiency and minimizing bottlenecks. In contrast, the Rotary Filling Machine offers standalone operation, providing flexibility in placement and usage across different production setups.

Filling Accuracy

The Rotary Filling Machine excels in delivering precise and consistent fill volumes, ensuring uniform product distribution within each container. While the Line Filling Machine offers excellent accuracy, it may be more suitable for applications where slight variations in fill levels are permissible.

Container Compatibility

The Line Filling Machine is typically suitable for specific container types, such as bottles or cans, with consistent shapes and dimensions. In contrast, the Rotary Filling Machine accommodates a wider range of container shapes, including jars, boxes, and irregularly shaped containers, providing greater adaptability for diverse packaging needs.

Changeover and Adjustability

The Rotary Filling Machine offers easy and quick changeover between different container types, thanks to its adjustable features and tool-less setup. The Line Filling Machine may require more time and effort for changeover due to its specialized configuration for specific container formats.

In summary, the Line Filling Machine emphasizes speed and integration into high-volume production lines, while the Rotary Filling Machine excels in versatility, precision, and adaptability to various container types. Choose the machine that best aligns with your specific production requirements and witness enhanced efficiency and productivity in your filling operations.

container capabilities

The types of containers our machine can accommodate.

Bottles

Versatile vessels, glass giants, metal marvels. With various shapes and sizes, including cylindrical, rectangular, and oval.

Cans

No can is too challenging for our line filling machine, as it expertly fills aluminum or tin cans with your liquid creations, guaranteeing airtight sealing and impeccable presentation.

Jars

With the ability to handle glass or plastic jars of all sizes, our line filling machine ensures consistent and accurate filling, making your products shine in elegant jars on store shelves.

Vials

Precisely fill vials and containers of all sizes with our line filling machine, guaranteeing the safety and quality of your sensitive liquids and pharmaceutical products.

A Guide to Pricing and Purchasing

Investing in packaging machinery is a critical decision that can have a profound impact on your production efficiency and overall business success. When it comes to line filling machines and rotary filling machines, finding the right solution that meets your specific needs requires careful consideration. To assist you in this process, we have compiled some valuable pricing and purchasing advice to help you make an informed decision.

Assess Your Production Requirements

Begin by assessing your production requirements, such as the volume of containers to be filled, the types of products you handle (liquids, powders, or viscous substances), and the desired speed and accuracy of the filling process. Understanding your specific needs will help you determine the appropriate capacity and functionality required from the machine.

Quality and Reliability

Consider the quality and reliability of the machines you are evaluating. Look for reputable manufacturers known for producing durable and high-performance filling machines. A reliable machine will minimize downtime, reduce maintenance costs, and ensure consistent and accurate filling results.

Customization and Flexibility

Evaluate the level of customization and flexibility offered by the machines. Look for features that allow for easy adjustment to accommodate different container sizes, filling volumes, and product variations. This adaptability will provide versatility and enable you to handle a wide range of packaging requirements.

Price and Value

While pricing is an important factor, it should not be the sole determinant of your purchasing decision. Consider the overall value that the machine offers in terms of its performance, reliability, ease of use, and potential for long-term cost savings. A slightly higher initial investment in a quality machine can yield significant benefits over time.

By carefully considering these factors and seeking professional guidance from our experienced team, you can make an informed decision that aligns with your production needs and budgetary considerations. Our commitment to customer satisfaction ensures that you receive the best pricing options, expert advice, and ongoing support throughout your purchasing journey. Together, let’s find the perfect filling machine solution that propels your business to new heights of efficiency and success.