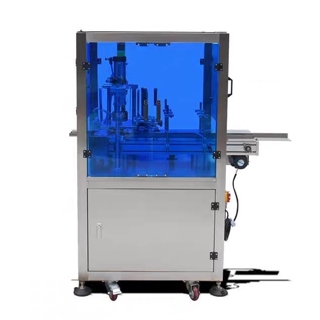

Rotary filling machine

Experience Unmatched Efficiency, Precision, and Versatility as you automate your production and achieve exceptional results. Perfect for jars, bottles, cans, or boxes, this state-of-the-art equipment is designed to streamline your operations and deliver optimal performance.

High-Speed Filling: Our Rotary Bottle Filling Machine boasts impressive speed capabilities, allowing for rapid and efficient filling of containers, maximizing productivity and throughput.

Precise Filling Accuracy: With advanced technology and precision engineering, our machine ensures accurate filling volumes, minimizing waste and ensuring consistent product quality.

Versatile Container Compatibility: From jars to bottles, cans to boxes, our Rotary Filling Machine accommodates various container shapes and sizes, providing unmatched versatility for your packaging needs.

Easy Maintenance: Our machine features a modular design that simplifies maintenance tasks, minimizing downtime and maximizing productivity. Regular maintenance and cleaning ensure optimal performance and extend the lifespan of the equipment.

Technical specification

| Model | RFL-A | RFL-C | RFL-LP | RFL-DCS |

|---|---|---|---|---|

| Type | Auger | Volumetric cup | Pump | Weigher |

| Products | Powder | Grain/powder | Liquid/paste | Grain |

| Range | 1-10g/5-25g 10-100g/25-150g 50-300g 100-500g | 1-10g 10-100g 100-500g | 1-10ml 10-100ml 30-300ml 50-500ml | 10-100g 50-500g |

| Container diameter | 20-80mm | 20-80mm | 20-80mm | 20-80mm |

| Container height | 40-140mm | 40-140mm | 40-140mm | 40-140mm |

| Capacity | 10-50 pcs/min | 20-50 pcs/min | 10-50 pcs/min | 10-50 pcs/min |

| Power | 3.5kw | 3.5kw | 3.5kw | 3.5kw |

| Dimension (mm) | 1400x1400x1850 | 1400x1400x1800 | 1400x1400x1800 | 1400x1400x1850 |

| Weight | 350kg | 330kg | 360kg | 400kg |

Video

FAQ

Q: What types of containers can be filled using this advanced machine?

A: This filling apparatus is compatible with a wide range of containers, including bottles, jars, tubes, and vials of different shapes and sizes.

Q: What are the advantages of using a rotary filler over other filling methods?

A: The rotary bottle filling machine offers high-speed operation, excellent filling accuracy, versatility in handling different products, and efficient production line integration.

Q: What are the control options available for operating this filling equipment?

A: The control system of this filling machine can be easily operated through a user-friendly touchscreen interface, providing intuitive control and monitoring capabilities.

Q: What safety features are incorporated into this filling machine?

A: This filling equipment is equipped with safety features such as emergency stop buttons, safety guards, and automated error detection systems, ensuring operator safety during operation.

Q: What maintenance procedures are recommended for this filling machine?

A: Regular cleaning, lubrication, and inspection of key components are recommended to maintain optimal performance and prolong the lifespan of this filling equipment.

Q: Can this filling machine be seamlessly integrated into existing production lines?

A: Yes, this filling equipment is designed for easy integration into existing production lines, providing a smooth and efficient workflow without major disruptions.